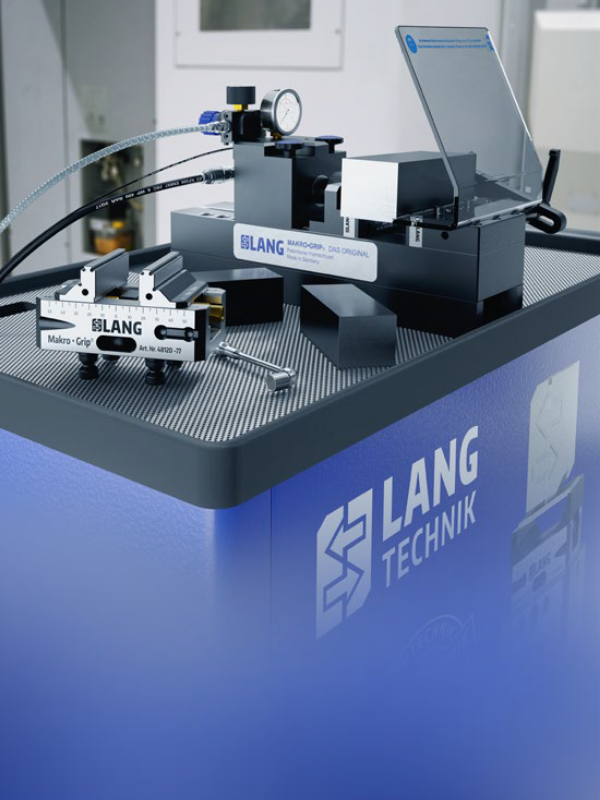

VISES

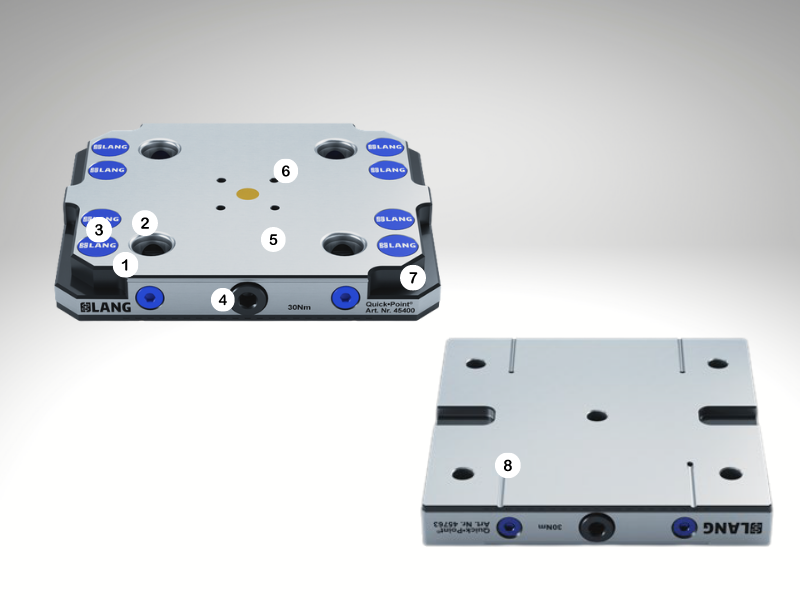

With over 50 different zero-point solutions and a wide range of customization options, LANG Zero-Point fixing systems are extremely flexible. As the interface between the machine table and the fixing device, Quick·Point® it is available in a very wide range of variants.

Form-Closure technology refers to a technology in which the part (up to a hardness of 45 HRC), which needs to be fixed is imprinted with a defined contour, with a hydraulic pressure (up to 20t), outside the machine tool, before being caught in the fixing device.

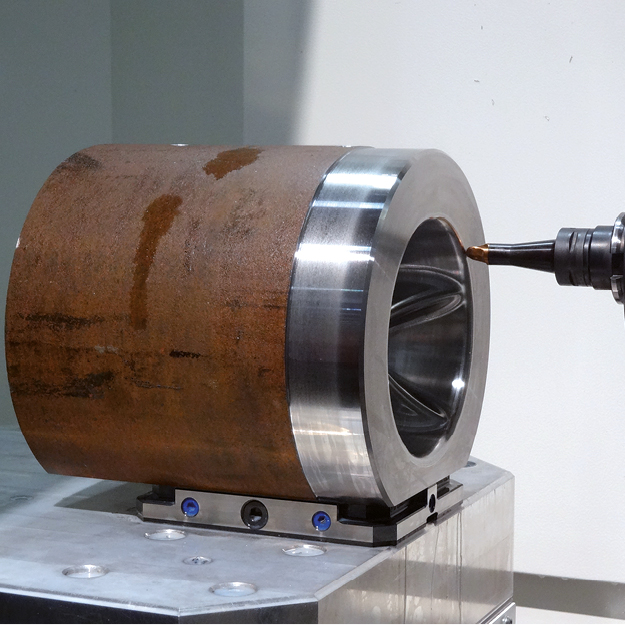

In combination with the Macro · Grip® 5-axis vise, Form-Closure technology guarantees the greatest gripping forces, accessibility and reliability of existing processes in 5-part processing.

External stamping

The stamping operation is performed offline. No machine tool is required to prepare the workpiece.

Form-Closure technology

Form-Closure fixing technology offers high clamping forces with low clamping pressure.

Material savings

The minimum requirements for fixing edges mean less material removed, during subsequent operations.

1- Cutting with a saw

2- Stamping

3- Fixing

5 seconds that revolutionize machining parts!

The workpiece is stamped directly on the saw cut or the slag layer of the blank.

The external impression allows the workpiece to be reliably fixed in the Makro · Grip® 5-axis vise with a low fixing pressure.

Deformation and distortion of the material during fixing are therefore excluded, and the wear of the fixing device is reduced to a minimum.

Its compact construction and the use of Form Closure technology make the 5-axis vise ideal for 5-part processing.

The benefits of the 5-axis Makro • Grip® vise

• Ideal accessibility in 5-sided processing

• The highest holding forces at low tightening pressure

• Fastening without distortion and without wear

• High material savings due to the minimum requirements for the clamping edge of only 3 mm.

• Process reliability and constant grip quality

• Ergonomic handling due to the lightweight vices

Stamping technology was invented by LANG almost 20 years ago and can be seen as the heart of the Makro • Grip® worktop.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |