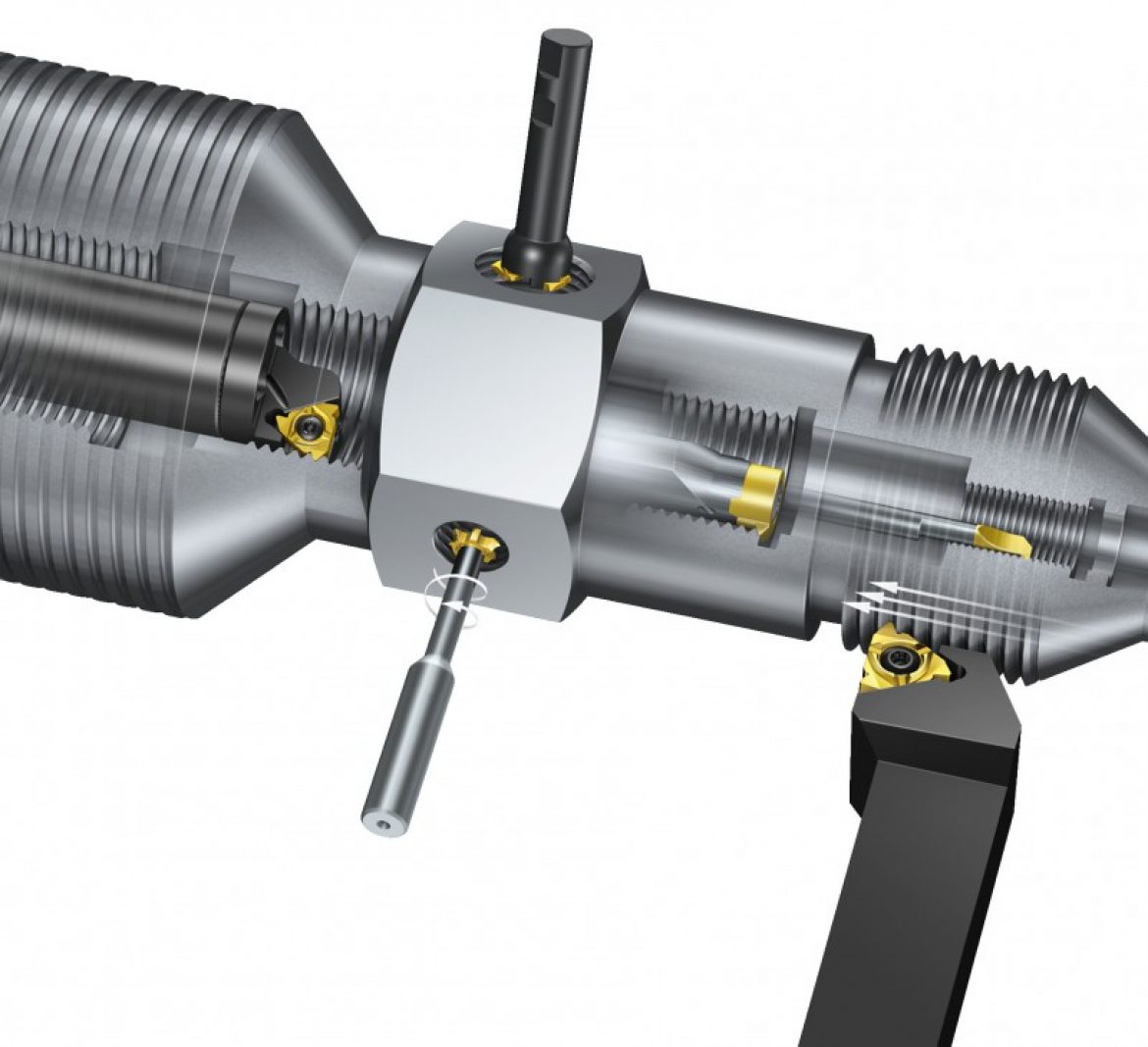

As a supplier of cutting tools for threading, Metal Star offers from top partners Vargus, Sandvik Coromant and Dormer - efficient solutions for all the usual methods of thread production, for internal threads in perforated holes and clogged holes, or for external threads.

Whether the methods are without cutting, such as thread deformation, or by cutting, such as tapping, thread milling, or thread turning, the high quality of the threading tools helps to achieve particularly high productivity, process reliability and profitability. In all commonly used materials, as well as in the really special ones.

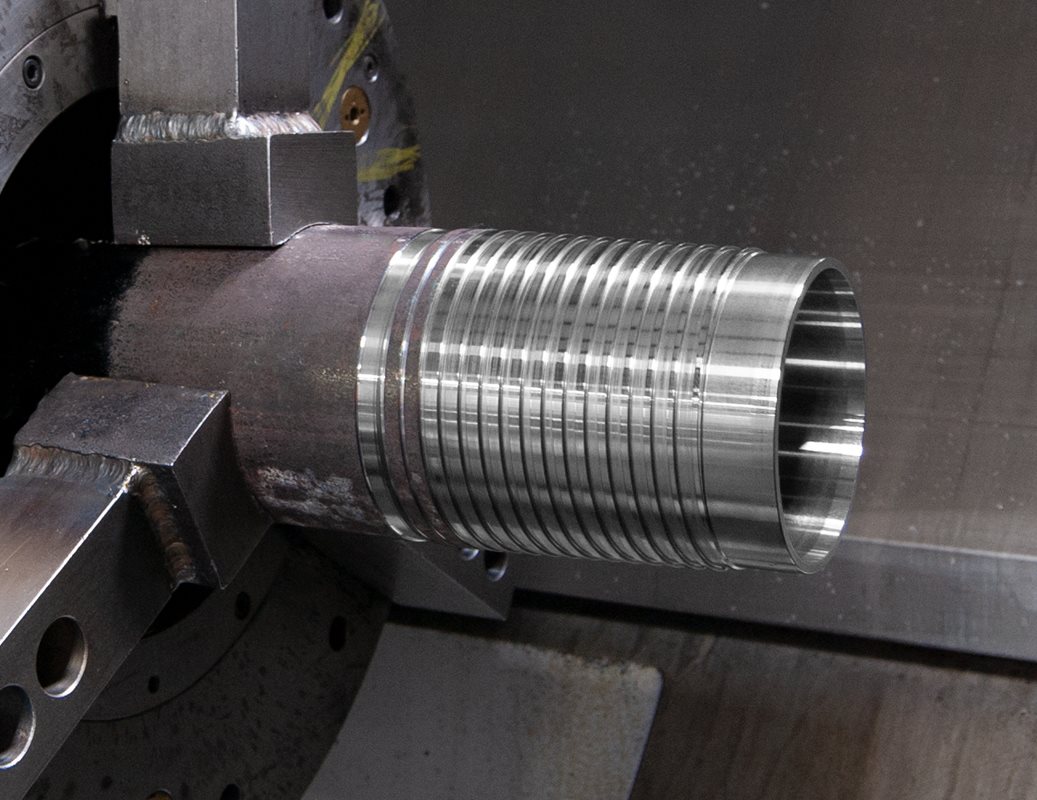

Cutting tools for threading can be used in the processing of parts in general mechanical engineering, as well as in the manufacture of punches and molds, in the automotive industry, oil and gas, energy, or aerospace.

The complete range of tools for threading different materials and diameters includes a wide variety of DORMER taps with the highest levels of precision, quality, cost-effectiveness and reliability of the process. For threading on any type of machine, from bench drilling machines to CNC machining centers, solid carbide or high-speed tool steel taps (HSS-E, HSS-PM) are available from DORMER.

In addition, we also offer buffer gauge range of all sizes!

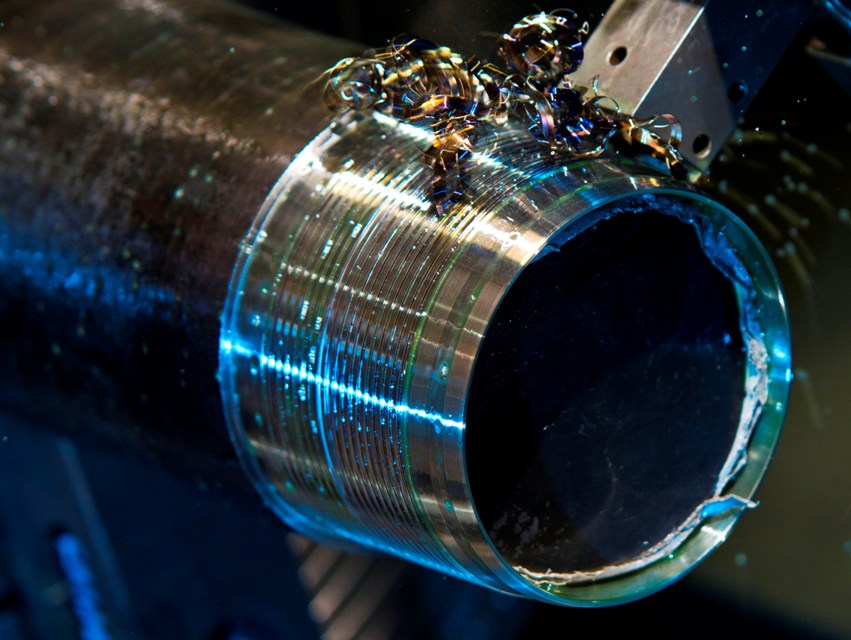

The high-quality coatings adapted to the material to be processed help achieve the production objectives, such as dimensional stability, short processing times, long tool life and, outstanding results in producing threads.