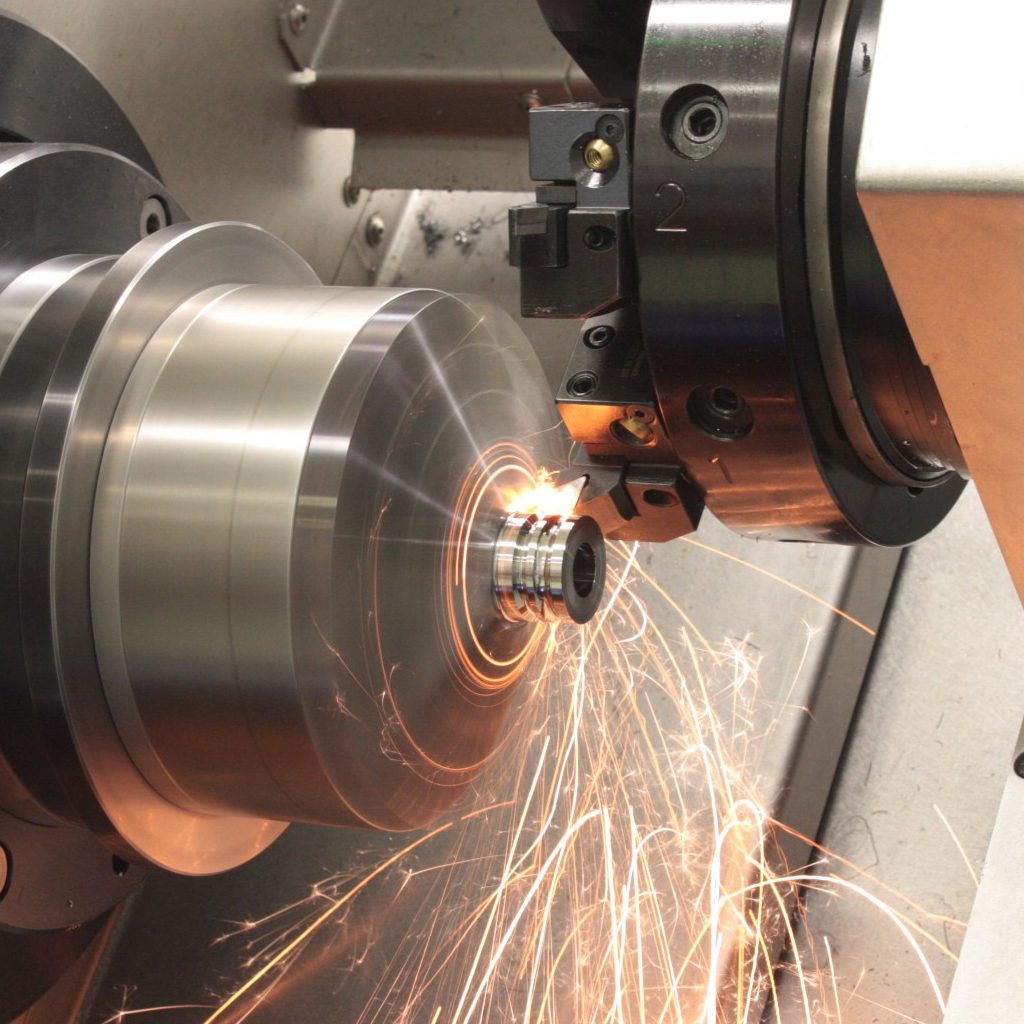

Whether machining with conventional lathes and automatic lathes or with the latest CNC-controlled turning and machining centers, Sandvik Coromant- our top supplier, offers cutting tools for innovative turning, which meet the highest requirements for all production processes involved in metal turning.

For longitudinal, frontal turning, grooved profiling and cutting, as well as for thread turning. Precision turning tools, boring bars and cutting blades are available with ISO standard square tails and Capto ™ supports for turning tools, as well as with all interfaces that are standard in turning applications. For you, this means: maximum flexibility, stability, productivity and repeatability on any lathe.

You will have the guarantee of obtaining top results for any workpiece!

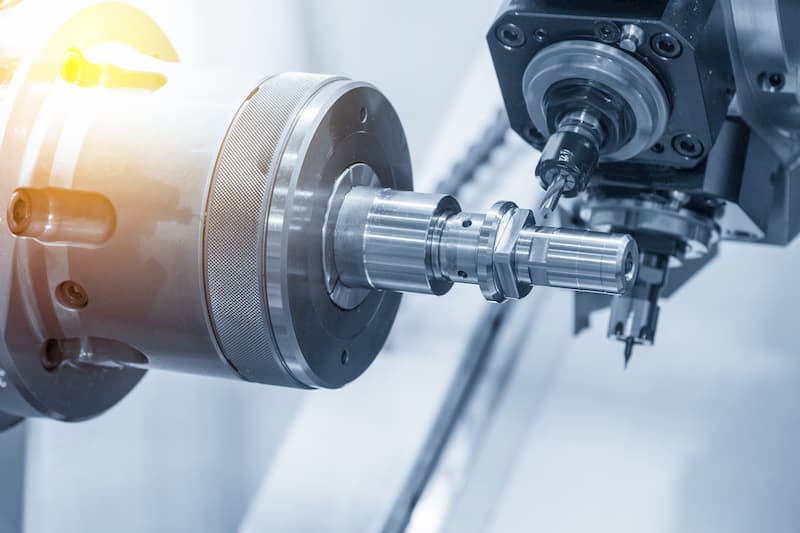

No matter what your machines look like or the machine tools you use - no matter what materials you work with: the complex expertise of Metal Star, which includes each individual turning tool, pays off. This applies to all production methods and turning applications.

For steel or stainless steel parts, as well as for aluminum and other non-ferrous metals or special alloys based on iron, nickel, cobalt and titanium.

Each of them is adapted to the processing material and has the best coatings for the material in question. Your advantages are the high reliability of the process, as well as an excellent quality of the surface finish and the dimensional stability of the component.