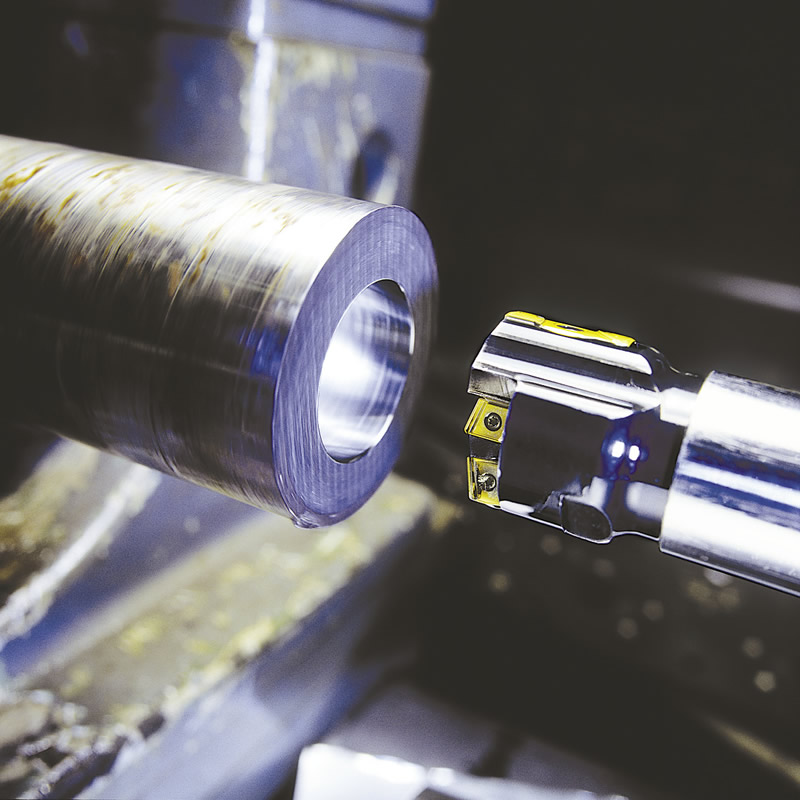

Metal Star offers through top suppliers Sandvik Coromant and Dormer a wide range of metal cutting tools.

Thus, we do not offer a drill for everyone, but professional drilling solutions that guarantee performance machining.

These drilling tools will help you complete your tasks with the utmost precision and remarkable efficiency, at any time, using a wide range of drilling machines and methods.

They are used in the processing of parts in general mechanical engineering, as well as in the manufacture of punches and molds, in the automotive industry, or in the energy industry.

In addition to helical drills made of solid carbide and high speed steel (HSS) with diameters from 0.05 mm to> 100 mm, our product range also includes various drills with indexable plates and interchangeable drill bits, in other words: drills with interchangeable tip.

The drilling tools are adapted to the material to be processed or to the specific application and complete our contribution to obtaining the best possible drilling results.

The strengths of Dormer drilling tools are best suited to the production of medium-sized batches.

This is because these metal drilling cutting tools combine low costs with excellent performance data and a wide range of products.