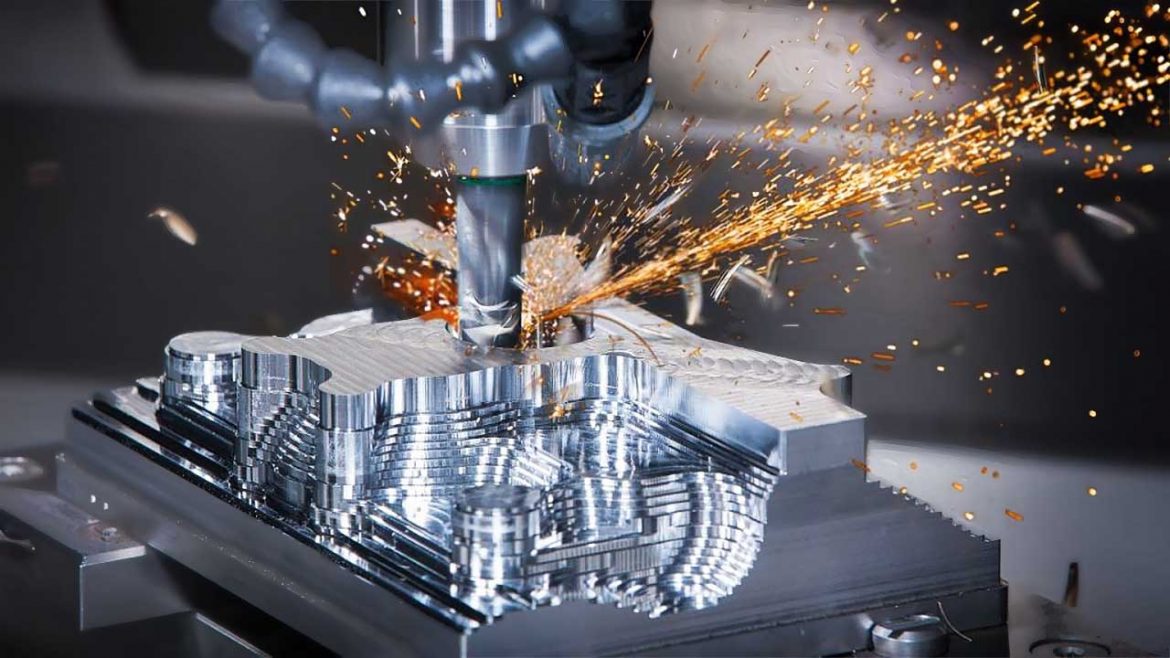

Metal Star offers you through suppliers Sandvik Coromant, Worldia, Dormer and Vargus a wide range from metal milling tools, which guarantees high-performance solutions for any metal milling requirement.

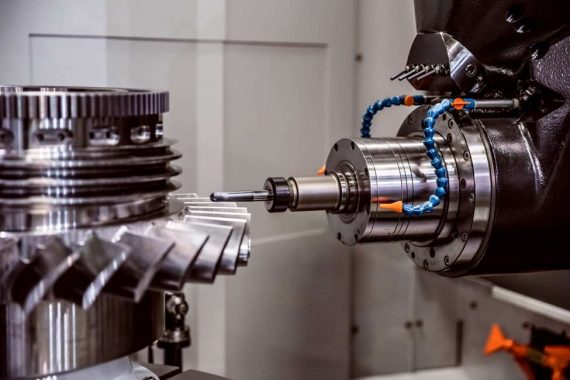

For use in CNC-controlled milling and processing centers, as well as for conventional milling machines - for large volume, as well as for medium and small batches.

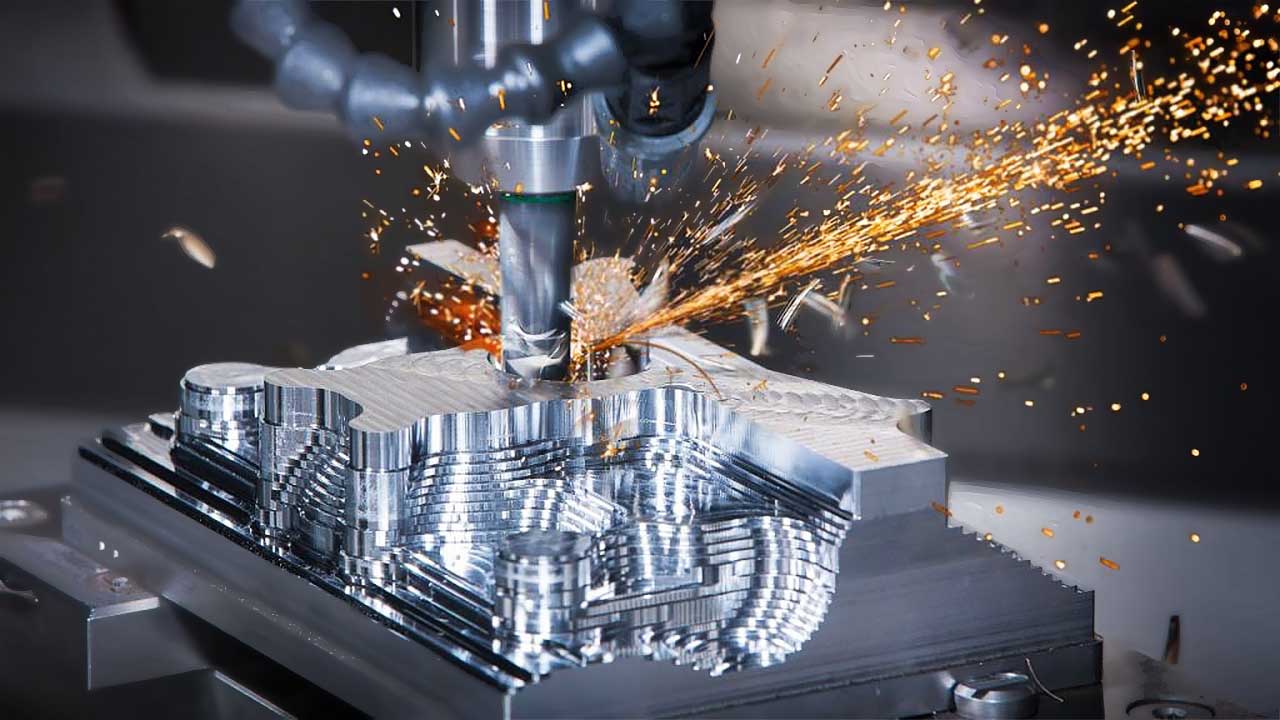

The same goes for general mechanical engineering and the manufacture of punches and molds, as well as in the automotive, energy, and aerospace industries - as a supplier of high-quality milling cutters and milling cutters with indexable plates, Metal Star can cover all needs in this field.

To allow you to further optimize metalworking applications and design them to be even more efficient, we provide milling cutters that offer high productivity, while providing perfect results from the first moment.

For each workpiece and on any machine!

Examples are for front milling and axial milling, contour milling and channel milling, copy milling and profile milling.

From solid carbide or tool steel (HSS) cutters, to special solutions with indexable plates.

In order to offer you the best possible cutter for any machine, any processing load and any material, alloys of materials for cutting tools and special surface coatings, adapted to the material to be processed, are used.

This results in milling tools that perfectly combine the high level of hardness of the cutting tool material with high surface wear resistance.