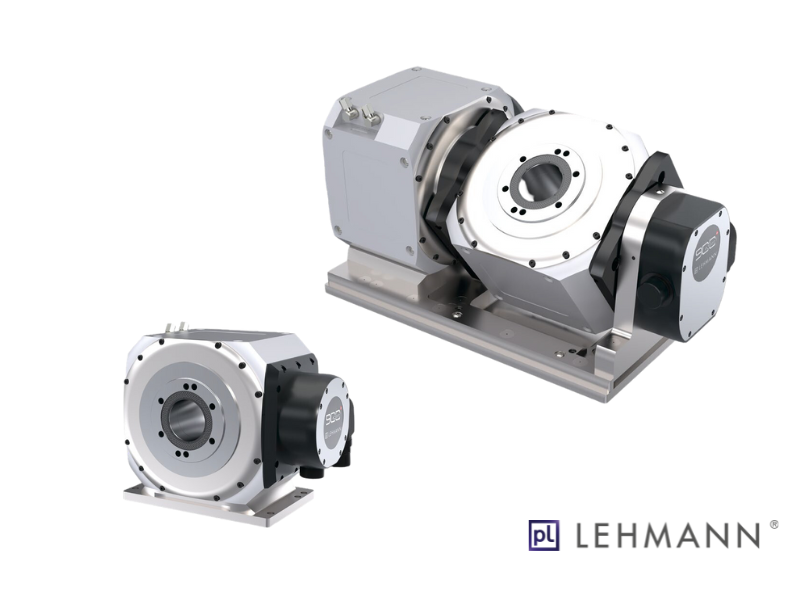

CNC rotary tables for economical production

pL LEHMANN has been developing and producing CNC rotary tables for over 40 years.

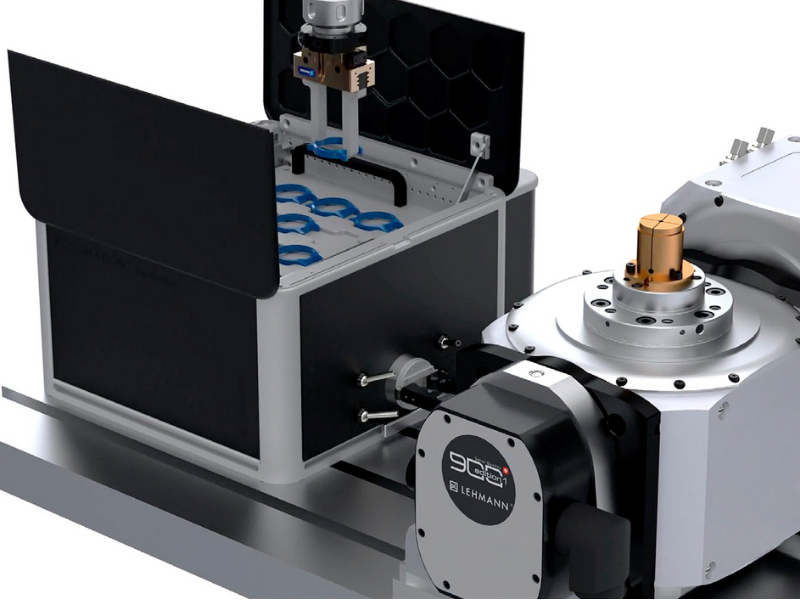

Metal Star va ofera de la pl Lehmann solutii adecvate cu innovative CNC rotary axes, organized in a standard modular system, solutions through which the Swiss manufacturer responds to the international needs of economic production of very small and medium-sized parts in the processing industry - by satisfying individual requirements with appropriate combinations.

- pL rotary tables used on over 200 different car brands and over 1,000 different car models.

- pL competence: integration in all known CNC control systems (Fanuc, Siemens, Heidenhain, Haas, Winmax, Mitsubishi, Brother, Mazatrol ...), for new machines, as well as for retrofits.

- Extremely productive solutions, even on compact machines for almost all requirements: 4 axes or 5 axes.

The accumulated experience and authentic Swiss quality is incorporated in the products and services offered.